I hope to start another loco soon, this time with the people at Peco having done the hard work on the body, so I can concentrate on making fewer mistakes with the chassis.

If you've seen the instructions for the 2mm Scale Association 08 shunter kit, you'll know what a good result an experienced loco builder can produce. I make no such claim, but I aim to learn through this experience, so that my next attempt will be better. Or as the philosopher said, "When one has finished building one's house, one suddenly realizes that in the process one has learned something that one really needed to know in the worst way - before one began".

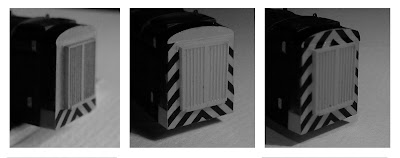

I had to re-drill the holes in the sides which were barely visible by now. Only problem I had was with one of the long 5-prong rails which I had to straighten out after failing to force it in. Once in place I secured them with some matte medium dropped into the holes with a fine paintbrush. Coming to the cab it's now clear that I've put the loco numbering too near the cab (in fact the numbers are too large), and the cab rail covers the nearest number. Rather than go back and reapply the numbering (I doubt I could do it as neatly again) I put the rail in at an angle.