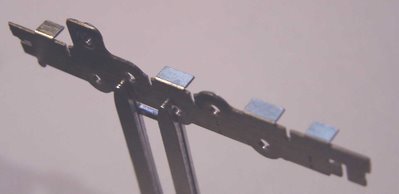

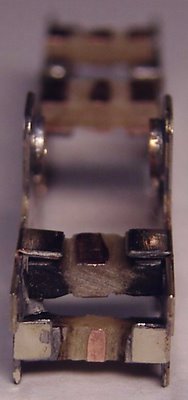

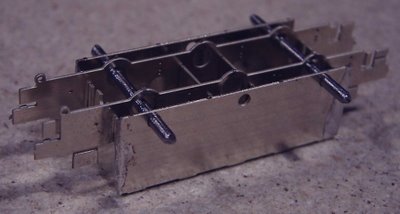

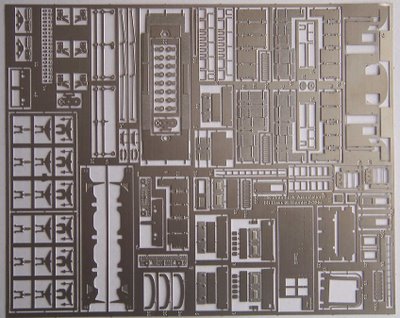

The underframe of the loco will obviously have to be a dirty oily colour when it’s done. I’m hoping I can get away without painting a lot of small delicate parts if I blacken them first.

I don’t think much of the chassis will eventually be visible, so this would be a good place to see how well it works.

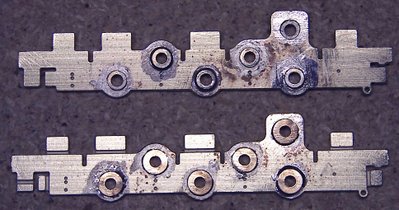

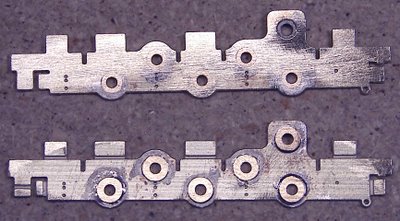

I bought some Birchwood Casey Liquid Blue once, planning to reduce the shine on the top of my rails. Haven't got round to that yet, but have used it for chemical blackening. It’s strong stuff (used on rifle barrels, apparently), and needs to be washed off in water as soon as the required colour is reached. I paint a little on a spare part of etch, and it starts to colour after a few seconds.

They give instructions on how to prepare the surface with some products I don't have, so I use liquid flux and wash off after a minute or so.

I don’t think much of the chassis will eventually be visible, so this would be a good place to see how well it works.

I bought some Birchwood Casey Liquid Blue once, planning to reduce the shine on the top of my rails. Haven't got round to that yet, but have used it for chemical blackening. It’s strong stuff (used on rifle barrels, apparently), and needs to be washed off in water as soon as the required colour is reached. I paint a little on a spare part of etch, and it starts to colour after a few seconds.

They give instructions on how to prepare the surface with some products I don't have, so I use liquid flux and wash off after a minute or so.